Boondocker Equipment Inc. is proud to be Syracuse's Krown Rust Control facility ready to keep your vehicle from weathering away. Krown offers the highest quality rust protection service available. Krown helps in extending the life of peoples' vehicles, reducing the cost of maintenance, while increasing the resale value of the vehicle. This saves the owners money, while providing peace of mind, knowing they have a safer, better looking vehicle. Our technicians are annually certified to ensure you are getting the best application to keep your vehicle protected. The proven preventative maintenance products and services is what sets Krown apart, and position Krown as Canada’s #1 Rust Protection Company. Soon, we will say the same for the United States.

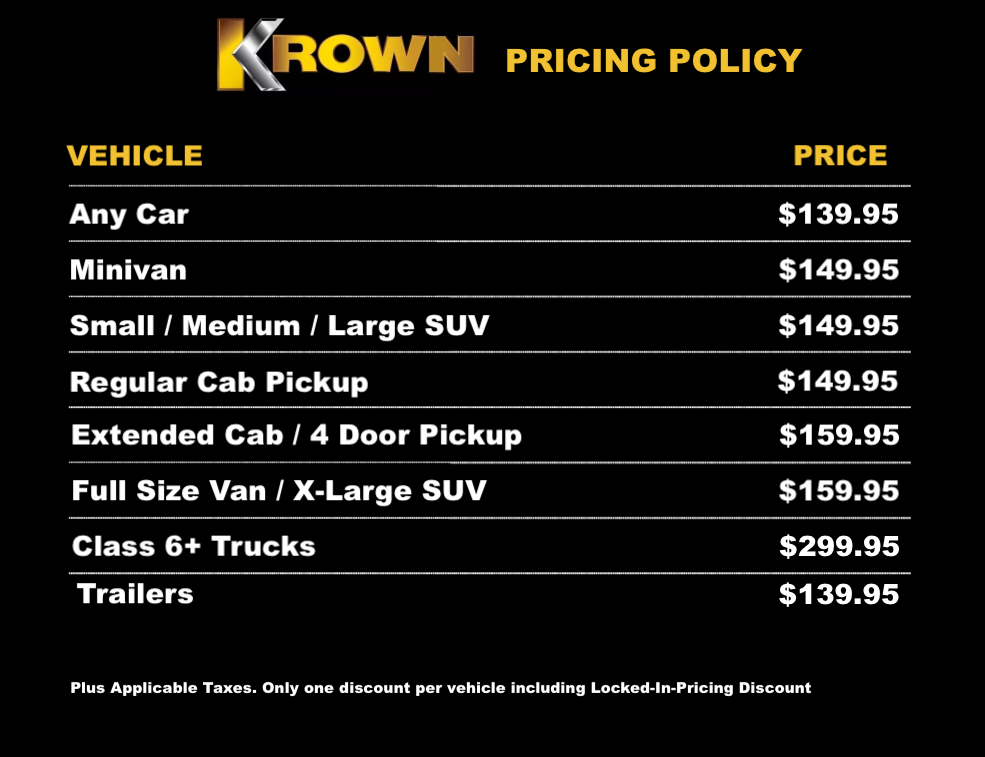

PRICING

Protect. Maintain. Save.

Give your vehicle the ROYAL treatment with Krown Rust Protection.

Ever wanted to see the Krown rust protection process? Ever wonder what salt trucks, de-icing solutions, and the winter weather do to your vehicle? Find the answers to those questions by watching this video.

FAQ

+ What is Krown?

Krown is not an 'oil spray' as such. It is a complex mixture of chemicals designed to slow down or inhibit corrosion on vehicles. It is a petroleum-based product, heavily fortified with rust inhibitors. Krown contains no solvents, kerosene, gasoline, no paraffin or wax, no lanolin, no toxic chemicals, nothing of a cancer causing nature, no aggressive chemicals of any kind - making Krown absolutely environmentally friendly. Krown is not controlled under WHMIS. The Federal Government (Canadian Food Inspection Agency) has done testing and has approved Krown for use in food plans where there might be some 'incidental' food contact. The testing involved is fairly aggressive. Krown is as safe a product as can be found in the marketplace for inhibiting corrosion on motor vehicles.

+ How does it work?

Krown is sprayed in every corner of the vehicle and as it contacts metal it bonds an ‘oily’ type film tenaciously to the metal. It ‘creeps’ into tight seams and crevices and will physically lift moisture off the metal and expel it. It then continues to repel moisture by setting up a moisture resistant bond on the surface of the metal. Krown is not water soluble and will not wash off bare metal with water or soaps. It would take fairly aggressive chemicals to take the product off bare metal. If a product will not displace and repel moisture, it cannot do an effective job in controlling corrosion.

+ Does it drip? Why? And for how long?

The product must get into the seams and around spot welds to work effectively. Therefore, it has to be fluid enough to penetrate. Once the ‘oily’ film bonds to the metal, more product will not bond on top of the film. Thickness has nothing to do with proper corrosion protection. Products that contain thixotropic agents such as paraffin or wax are too thick, too heavy to get where most corrosion begins, that is inside tight seams and crevices where condensation and moisture can collect. Thicker, heavier products may give the consumer some ease of mind that a lot of something has been sprayed in open spaces where it can be seen. Unfortunately, most corrosion gets started in areas not visible to the eye. With Krown, beyond the ‘film’ that bonds to the metal, a small amount of excess product will weep gradually from drain ports at the bottom of the doors and from some of the seams. The majority of the dripping occurs within 24 hours with very little, if any, dripping after that point. Generally speaking, within about 6 – 8 hours most of the dripping is done. There is nothing in the product to harm asphalt or concrete and it will not eat into pavement like oil does. Any spotting that shows on a paved or concrete driveway will eventually disappear by itself. However, with interlocking brick, it is recommended not to park on it for a couple of days due to the fact that the brick is very porous and tends to absorb the stain and the spots will stay much longer than on asphalt or concrete before eventually disappearing.

+ Is Krown effective in treating vehicles with existing rust?

Both new and used vehicles have rust on them and the Krown Rust Control product works on either. Krown is absorbed into existing corrosion and pushes out any moisture present, thus significantly slowing the corrosion process. If a product is thick and heavy, it tends to ‘coat’ the existing corrosion, trap condensation and moisture underneath and in many cases actually accelerates corrosion. Moisture on metal - not salt - is the Number 1 cause of corrosion. Salt is an accelerant much like gasoline. If you have a small fire burning and add gasoline the gasoline greatly accelerates the fire. Salt is not the primary cause of corrosion but in the presence of moisture on metal it does greatly accelerate corrosion. For that reason, any product that is going to slow corrosion on metal to a virtual crawl and give you a fighting chance at making the body of your vehicle outlast the engine and drive-train, must have the ability to remove moisture from the metal and not allow it back into contact with the metal. Remember, from day one, all metal wants to return to its natural state as an iron oxide. It is much like us. From the day we are born we begin the process of aging until we die. We may eat all the health foods we can find, take vitamins, exercise, not smoke and not abuse alcohol and take all the measures we possibly can to extend our lives, but unfortunately we still grow old and die. The metal in your vehicle is no different. The truth is, there is no product available in the marketplace today that can absolutely, totally stop rust, just as today there is no doctor or hospital that can stop the aging process. The best anyone can do is interfere with that process. But one thing is for sure, Krown has always substantially outperformed any of our competitors in the area of annual application ‘oil’ type products used for rust control. Ask to see the test results when you are at a Krown center. And the Krown product we currently spray on vehicles is the best it has ever been, thanks to an on-going research and development program that has seen the same chemist overseeing the development of the product for the past 20 years.

+ When is the best time of yest to have my vehicle sprayed?

The best time to spray your vehicle is right now if you have not already done so! However, from a corrosion point of view, most corrosion (about 20% - 40% more) takes place in the spring due to the increase in temperature and moisture. Once the temperatures begin to rise in the spring and the metal warms up from increased outside temperatures, any ‘salty’ residue left over from the winter months in seams and crevices and hidden areas, really goes to work. In the standard testing methods used by laboratories for testing these type of products (ie; ASTM-B117 Salt Spray Cabinet Test) part of the testing process involves raising the temperature within the salt spray cabinet to, for example, about 95°F. The higher temperature inside the cabinet greatly encourages the salty moisture to aggressively attack the metal panels used. Therefore, Spring and Summer are excellent times to have a vehicle treated. And with Krown Rust Control, the product will creep a little faster in the warmer weather to get into the seams and crevices to neutralize the effects of salt and moisture on the metal. There is no “bad” time of year to spray your vehicle to protect the metal from corrosion, but the product is good for a year, regardless of the time of year it is sprayed and spraying it in spring or summer means the product will be there and active on the metal when winter comes and the snow begins to fly and the salt truck begins to spread the terror for another season. Once a year is sufficient to spray the vehicle to make the body outlast the engine and drive-train.

+ How do you know where to spray to access all the critical areas?

All Krown technicians are trained according to specifications set out by Krown Head Office. Once a year all technicians attend an annual training seminar to upgrade their skills as well as to receive updates on any new techniques for current vehicles and to become proficient in the use of any new equipment made available to improve the quality of the job we do. As well, Krown Head Office from time to time provides updated tapes and CD’s demonstrating the proper application process. These may be consulted at any time by our technicians in order to ensure the proper application procedures are being adhered to on all vehicles. Krown Head Office also provides, on a regular on-going basis, actual pictures of new vehicles that come into the marketplace, showing any special access points for drilling that may not be shown in our standard spray pattern for cars, pickup trucks, SUV’s, minivans, etc. All Krown dealers also have access by code to a log-in site on Krown’s Head Office website at www.krown.com. There, any of our sprayers may access up-to-date pictures of new vehicles in the market and the drill pattern that should be followed to ensure that we access all critical areas on that vehicle. Being that the Krown warranties are backed by Krown Head Office, we want to ensure that proper procedure is used in all vehicles thus reducing as much as humanly possible any need for legitimate warranty claims. Naturally we want to protect our own interests and we cannot do that without automatically protecting the interests of our customers as well.

+ Doesn't washing the vehicle immediately afterward defeat the purpose of spraying it with Krown?

The reason for washing it immediately afterward is to take any small amount of over-spray off the paint and window glass. Krown will not harm paint or clear-coat in any way. However, leaving it on the paint will only pick up light dust and keep the vehicle looking dirty. Also, we want to ensure that the windshield is clean so that no smearing occurs when windshield wipers are in use. Soap and water will not take the product off bare metal, which is where you need the product to remain present. Krown will not penetrate the paint itself, therefore, we do not spray the paint and there is no benefit in leaving it on the painted surface. A light wash afterward ensures that you drive your vehicle away clean……and you can see!

+ Why do you have to drill holes and will these holes rust?

Certain areas of a vehicle can only be accessed by drilling small unobtrusive, holes in key spots. The holes are drilled using a special ‘uni-bit,’ not an ordinary drill bit. A uni-bit gives a nice clean cut and does not wander like an ordinary drill bit has a tendency to do. It also does not chip the paint around the hole. After spraying, a special compound is lightly brushed on the hole to treat the bare metal, after which each hole is plugged with a special manufacturer’s grommet that can be removed each year and after a complete application, the holes are re-plugged with new grommets. In addition, due to the ability of the Krown product to “creep” on the metal, a light film will tend to creep out around the plugs to form a small circle around the plug. This can be easily removed by wiping the painted surface around the plugs with a cloth. But this ensures that no moisture is allowed to enter or remain on the metal underneath the plugs. Concerns about rusting around the holes go back to the days when thick, heavy wax or tar based products were used. These tend to stick where they hit and do not do well in creeping or displacing moisture. Some products are promoted as “NO-DRIP” products. The likelihood that a product can be “NO-DRIP” and yet can “creep” in any direction on the metal to get where you really need it is about as likely as saying that a cowboy jumped on his horse and rode off in both directions! Not likely! Also, think about this: your vehicle is held together by several thousand spot-welds. These are like the stitches that hold a garment together. Most garments are not one big stitch. Most are held together by hundreds or even several thousand small stitches. What happens if you take a pair of scissors and randomly cut individual stitches here and there on the garment? One day you bend over to lift something and the garment tears away where the stitches had been damaged. Your uni-body vehicle is not much different. The cage integrity or strength of the body in an accident depends on the strength of the ‘stitches’ or weld points, does it not? Where does corrosion usually start? Body men or women who work on vehicles all the time know it starts in hidden areas such as seams and crevices and around spot welds. This is because those are areas where moisture condenses and tends to hide. As small pockets of corrosion begin to form in those hidden areas the ‘stitches’ in your vehicle begin to weaken. One day if you are unfortunate enough to be involved in a collision the cage integrity is greatly compromised to a point where the protection in an accident is no longer there resulting in a greater chance of serious injury. So what will weaken the body more; the few small 3/8” holes used to get the Krown product to those ‘stitches’ and body panels to keep them healthy and strong or not properly accessing those hidden areas and allowing corrosion to get a foothold so that the cage integrity is greatly compromised? The answer is obvious. It would not be wise to let anyone talk you out of treating your vehicle simply because “they drill holes.” So the following question will likely readily come to mind:

+ Will getting my vehicle sprayed with Krown void my manufacturer's warranty?

Simply stated: NO! Krown Rust Control will not void any manufacturer’s warranty in Canada. Given the laws and regulations governing warranties and guarantees in Canada, vehicle manufacturers cannot absolve themselves of their responsibilities to consumers by saying that if you use aftermarket parts or products on your vehicle you will void the manufacturer’s warranty. That is not the case and consumer groups such as the Automobile Protection Agency (APA) will verify that. A government registered document, the Magnuson-Moss Act also verifies that. The Magnuson-Moss Act was enacted in the United States but applies equally as much in Canada due to the Auto Pact between the two countries. No one country can have an unfair advantage over the other. So if you wish to use aftermarket parts or products on your vehicle you may do so and no one can void your warranty as long as you follow the prescribed maintenance schedule. To be fair, if a product or application causes damage to some part of the vehicle, it goes without saying that the manufacturer is not responsible for the damage. Therefore, the damage would have to be repaired by the manufacturer or installer of the aftermarket part. But the application of any aftermarket part or product does not in and of itself void the manufacturer’s warranty.

+ Why is the Krown Rust Control product better than dealer rust-proofing?

Most dealer products are designed as coatings, leaving many critical areas of your vehicle untreated. Or worse still, those coatings have been known to actually block drain ports at the bottom of doors, trapping water to a point where you sometimes had a virtual fish tank inside the doors. Water trapped in seams and crevices in the winter tends to freeze. Freezing water expands and in time freezing and thawing will actually cause seams to open up, letting in more moisture to freeze and thaw and perpetuate the damage. Krown will not allow that to happen. Krown is designed to creep into the seams and crevices as an ‘oily film’ that does not harden, crack or peel. Once in the seam it will physically lift moisture off the metal and expel it. It does not trap moisture. There are also many advantages to the Krown Warranty against corrosion on qualified vehicles over the dealer warranties. Check the fine print on any warranty issued. Many are not worth the paper they are written on. Krown’s warranty on new vehicles covers, in writing, all body panels below the window line, all floor and rocker panels and all seams and crevices against rust perforation from inside out. Most warranties do not cover seams. Krown does because the product actually creeps into the seams to protect them. In addition, Krown is a natural lubricant and penetrant. Inside the doors it treats all moving parts to keep them from seizing and is designed to work with the electrical and electronics on modern vehicles to keep electrical contacts clean and electrical and electronic components functioning properly. KROWN WILL NOT HARM ANYTHING ELECTRICAL OR ELECTRONIC ON VEHICLES. It can safely be sprayed on electrical switches, wiring connections, battery terminals; even circuit boards and computer chips. It does not HARM the electrical; it actually HELPS AND PROTECTS anything electrical on your vehicle. While it is good to keep your vehicle looking good in terms of body panels, what about keeping all the working mechanisms inside the doors freed up and working? How about door locks, trunk lid locks, door hinges and hood latches? What about keeping brake cables from seizing and protecting brake and fuel lines and components such as fuel tanks and oil pans. While these components are not covered by warranty, an annual application of Krown will greatly extend the life of those components, thus reducing mechanical and electrical repair costs over the life of the vehicle. Those are areas that dealer rust-proofing do not adequately address. And there is no such thing as a ‘one-time’ system that works well just as you cannot just change the oil ‘once’ over the life of a vehicle if you want it to function properly. Regular mechanical maintenance involves periodic attention to brakes, spark plugs and wires, transmission oil and filter changes etc. The body is no different. If you want to get the best out of your vehicle the body needs something done on a regular, periodic basis to ensure that it does not go to the scrap yard with a good heart and skin cancer. It is not our intention to bad-mouth the product used or the job done by dealers. We are simply saying that what Krown does is different….and, we feel, substantially superior.

The other aspect of this is that dealer rust-proofing requires a large sum of money up front. Should you be unfortunate enough to be involved in an accident or have your vehicle stolen in a year or so, you will have paid for a so-called “lifetime” of protection from which you will not realize the full benefit for which you have paid. The insurance company will not likely reimburse you for the rust-proofing package you purchased. With Krown you pay as you go. You get a complete annual application, not just a ‘touch-up’ or ‘inspection.’ Everything gets done thoroughly again; all body panels treated annually, all moving parts and electrical connections treated annually, completely. If you decide to keep the vehicle next year, you can spray it again. If you are not keeping the vehicle or if it has been written off in an accident or stolen and not recovered, you are not paying for rust protection from which you do not derive the full benefit for which you have paid. We feel this is a much more reasonable and economical approach to rust control. Krown is the largest company in rust control in Canada today and we manufacture the product we spray. Therefore, we stand behind it all the way.

The truth is, there is no perfect solution to rust control in our kind of climate. In Northeastern United States, surrounded as we are by the Great Lakes, and where the relative humidity at any given time is about 30-40%, sometimes as high as 90-100%, we must contend with the presence of moisture on metal. Add the inclement weather we experience in winter and increased effects of road salt used and you have a near perfect recipe for corrosion. The need for a product to have the ability to penetrate tight seams and crevices and expel moisture from the metal cannot be over-emphasized. Moisture is the #1 cause of corrosion on metal. Take two identical vehicles that come off the assembly line within a few minutes of each other. Put one in Northeastern United States for 10-15 years and put the other one in Arizona. In 10-15 years, which one will have the most corrosion visible? It will be the one in Northeastern United States. It is not so much the presence of air or oxygen contacting the metal, it is rather, the moisture content of the air. They do have air in Arizona. People do breathe! But the air in Arizona is very dry with very little moisture present. Therefore, very little moisture can condense on the metal. Hence, very little corrosion problems. Krown works, and works very well, because it has demonstrated the ability to displace moisture better than any competitor product currently in use as an annual system for inhibiting corrosion in our Northeastern climate.